Approach parts classification and reuse the way Gmaild did: Let the machines do the work

See how Standard Parts Managament makes short work of a Parts Classification and Reuse Initiative

As business, engineering and manufacturing has moved deeper into the digital age they have found a myriad of new consequences and side effects stemming from the very tools they use to simplify their lives.

Twenty years ago my email inbox was a clean slate. This was 9 years before Gmail had launched, I had an email address which I could access from one program, on one PC. Yes, the program was Eudora Pro and it was on a pretty sweet 486 desktop machine, with a 20” monitor that weighed 150 lb!

I would only get an email or two a week. I’d read it and either delete it or file it away. If you had told me I would need a powerful search to find a specific email I would have literally, laughed out loud. A method to automatically sort messages into different folders? I’m pretty sure I can handle the work-load here!

As things have progressed digitally, the volume of electronic communication has grown exponentially. I recently returned from a couple of weeks of vacation “off the grid” only to find more than 100 messages in my Gmail “Primary” Inbox, and more than 500 in the “Promotions” folder and another pile in the “Social” inbox. You see, Google Gmail has learned which messages are important, based on who sent them, the subject line etc. This saved me some serious time when I returned home from vacation. I could simply ignore, or at least deprioritize the promotions and social folders, and focus on the messages Gmail told me were important (BTW they’re right about 99% of the time).

How’d they do it? Well I can tell you how they didn’t do it. They didn’t have a dude in a room sifting through your messages manually, previewing and sorting them into the proper folder. Instead, they did created a cool program to learn and sort messages into the appropriate bucket. They let the machines do the work!

Now that my inbox is clean, I needed to find an old email. By “clean” I mean that I don’t have hundreds of unread messages, but there are still thousands of messages in there (11,806 to be exact) just piling up. There was that one email though, with that BBQ recipe from 5 years ago, that would be great for this weekend. Gmail has me covered. I can search my inbox about eight different ways, by subject line or message content, by attachment, by date, size etc. I found that BBQ brisket recipe in about 2 minutes, too bad I can’t cook it that fast!

So what does any of this have to do with Manufacturing and Engineers? Anyone working with digital parts has the exact same problems I have with my inbox. The data has piled up faster than anyone can clean it up. They need the ability to quickly find and reuse parts for their designs. They also need new files to be sorted and tagged automatically. The typical solution to make these thousands, or millions of parts more accessible, is a “Classification and reuse initiative”. This is where an engineering team sits down, decides which parts they need, what to call them, what meta-data to attribute to them and how to sort them. It’s a big job that sounds a lot like Gmail having a “guy” who sorts my email for me. Once the job is “done,” companies still need someone to do this for every new part that comes into the parts library, forever.

Manufacturers facing a classification and reuse strategy have three options.

- The Ostrich Technique: Pretend the problem doesn’t exist and proceed as normal. Costs will continually increase and productivity will diminish.

- A Traditional Classification initiative: A large labor-intensive project, lasting years, which will require manual tagging and sorting of parts for perpetuity.

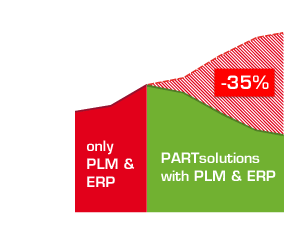

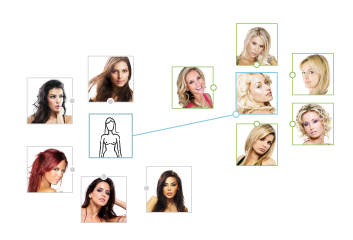

- Standard Parts Management PARTsolutions: CADENAS Standard Parts Management software PARTsolutions “crawls” and indexes all of a company’s parts in their various locations. It can search disc drives, PLM systems, ERP systems and more. It then builds an index of parts based on dozens of criteria and attributes. Now, engineers can find parts by using a selection of search methods, including GEOsearch, sketch search, attribute search, dimension search etc. The best part? Every new component that comes into the system is indexed, tagged and added to the search so no manual work is necessary. Engineers can find and reuse parts much more efficiently, reducing design costs and increasing profitability.

Seems like an easy decision doesn’t it?