Littleford Launch Interactive Design Tool Powered by CADENAS to Expedite the Specification Process

All new interactive design tool cuts design process from weeks to days

Littleford Inc. maker of industrial mixers, dryers and reactors, have launched their all-new interactive design tool. The online resource, built by the CADENAS US subsidiary CADENAS PARTsolutions LLC enables a customer to design their machine online, to their exact specifications, in real-time. Offering infinite configurable variations, the interactive tool enables customers to receive quotes much more quickly as well as saving time on design iterations and revisions. The process to design and specify a Littleford product has been reduced from six weeks to just days.

Best known for the Littleford Mixer, the Cincinnati-based manufacturer has expanded their business, positioning themselves as not “just another industrial manufacturer,” but as a “Process Solution Partner,” delivering much more than industry leading machinery. Their new interactive design tool is a key component of their new identity, enabling customers to design their own machine or to enlist a member of the Littleford team to guide them through the process.

Formerly, the process to specify a Littleford machine would take up to 6 weeks, from preliminary discussions to the initial general approval drawing delivered to the customer. This was partially due to the custom nature of each project, but also due to inevitable customer design iterations and revisions. Now, this process has been shortened to a single day with the interactive design tool. Furthermore, the customer is able to try multiple iterations in that day.

“We looked at our design process and really analyzed what steps took the most time,” adds Mark Ortiz VP of Engineering at Littleford Inc. “Previously, we would have initial discussions with a customer and design the machine per their request. We would then send them drawings of the machine, which is when new questions or ideas would come up. This resulted in many design iterations which is time consuming for our engineering department and the customer as well. Now, customers can create the machine in real time, watching it develop visually. This helps get the ideas and questions flowing in the initial meeting and really speed up the entire design process.”

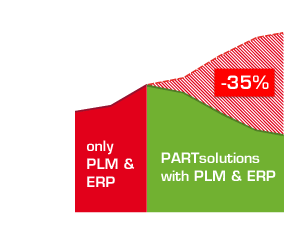

Littleford uses CADENAS software to manage multiple aspects of their business. They utilize eCATALOGsolutions software to power their interactive design tool, as well as implementing PARTsolutions Standard Parts Management (SPM) software for their engineering team.

“This project is really the ‘perfect storm’ for the CADENAS PARTsolutions family of products,” adds Robert Zesch President and COO of the CADENAS US subsidiary, CADENAS PARTsolutions LLC. “Littleford has greatly reduced their delivery time for quotes and orders with the interactive design tool. This will really boost the ease of doing business for their customers. They’ve also implemented our SPM tool to search, sort and organize all of their standard parts internally. Now, every industry standard, supplier standard and internal standard component for their products is organized within the SPM software. This will streamline their engineering processes and reduce duplicate parts in their system, another boost for the bottom line.”