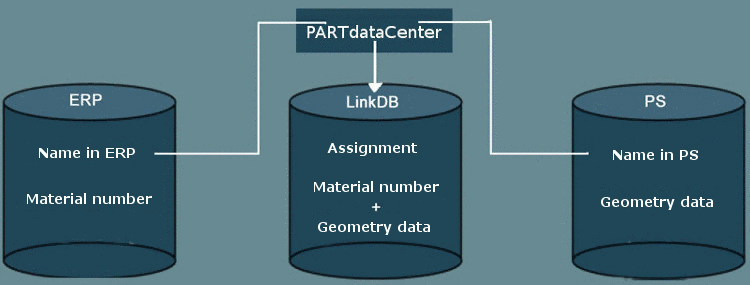

The LinkDB creates connections between the geometry data of standard parts and supplier catalogs and ERP data from different systems and databases. This connection must first be established.[12]

PARTdataCenter and PARTident are tools that can identify - even with differing descriptions.

A part is basically identified with a standard number and a specification of the attribute.

For example: ISO 4762 and M5x25

Parts that were identified are saved in the LinkDB with the connection material master number + geometry parameter.

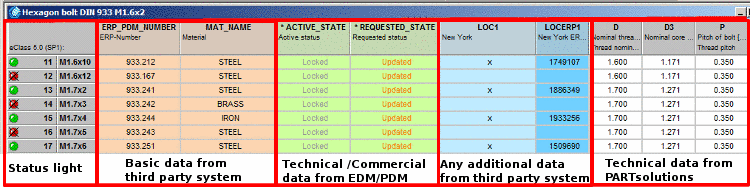

Based on this connection, several other Attributes/information can be allocated and added from the third party system. All information can then be displayed in the PARTdataManager - either completely or partially filtered.

Via the number (ERP_PDM_NUMBER) data can also be easily identified and updated. See Section 1.7.2, “Keep data up-to-date ”.

All data can be displayed in one single interface in the PARTdataManager.

[12] Basic information about connections (link table, ERP table) can be found under Section 1.7.1.3.1, “Link table and ERP table”.