The LinkDB establishes the connection between the geometry data of the digital libraries and the ERP data from different systems and databases. This connection must be set one time only, since identical parts with different identifications will be entered into the different systems. For example, one time as M8x12 and another time as M08x012.

With the help of PARTdataCenter CSV information can be identified and assigned to parts - even if showing some differences in naming. See Section 1.1, “ Article assignment (initial filling of LinkDB) ” in PARTwarehouse Manual.

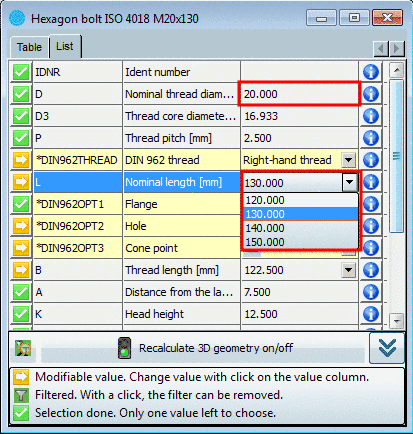

With standard parts, a part with Standard number and declaration of characteristics is definitely identified.

Exemplary would be: ISO 4762 and M5x25

Identified parts are saved in the LinkDB with the linkage Material master No. + Geometry Parameter.

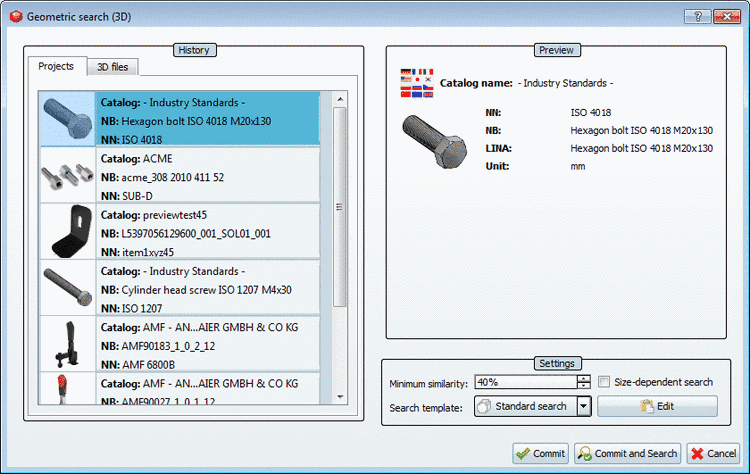

Because of this linkage, PARTdataManager now displays any further Attributes information from the ERP system. If the relevant part is known in other systems with the number as well, then all other attributes can be attached as well.

Furthermore geometric variants will be saved in the LinkDB and not in the original tables. Thereby catalog updates can be performed without the risk of data loss.

The advantage of the LinkDB recapitulate therein, that data exchange and communication between different systems is possible without damaging the integrity of the involved systems.

All the information can then be shown in only one user interface.