Test part

checks the part integrity, to ensure a faultless

export to the different CAD systems.

checks the part integrity, to ensure a faultless

export to the different CAD systems.

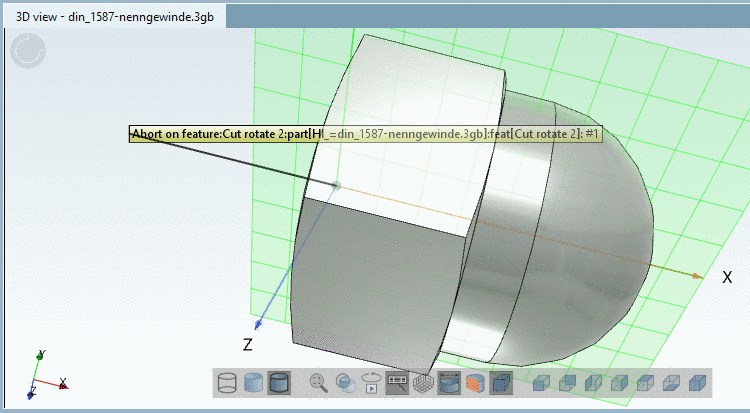

If, in the course of the test run, problems arise, this is directly documented in the 3D view of the part (see figure).

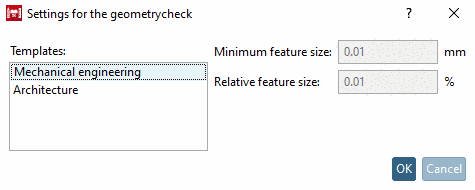

-> The dialog box Settings for the geometry check is opened.

Please select the appropriate template. In this way Minimum feature size and Relative feature size are set.

Mechanical engineering parts may not be tested with the setting Architecture, for example. In contrast, BIM parts must be tested with Architecture, so that export problems to Revit, for example, caused by features < 1,4 mm are avoided.

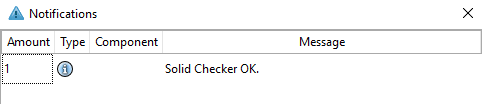

-> In the docking window Notifications, a respective note is displayed.

Also see Section 7.9.8, “Problem avoidance ”.

![[Note]](https://webapi.partcommunity.com/service/help/latest/pages/en/partsolutions_user/doc/images/note.png)