Start PARTdataCenter and click on PLM Synchro.

-> The PLM Synchro Wizard is opened.

This wizard guides you through the PLM Synchro setup process.

Choose the desired Project path via search button .

You can create the process File based or PDM based.

In the list field, select the desired interface and with the search button , choose the Download folder.

The PDM interface can be configured directly from the Wizard.

-> PARTadmin is opened and the respective block in the configuration file is already preselected.

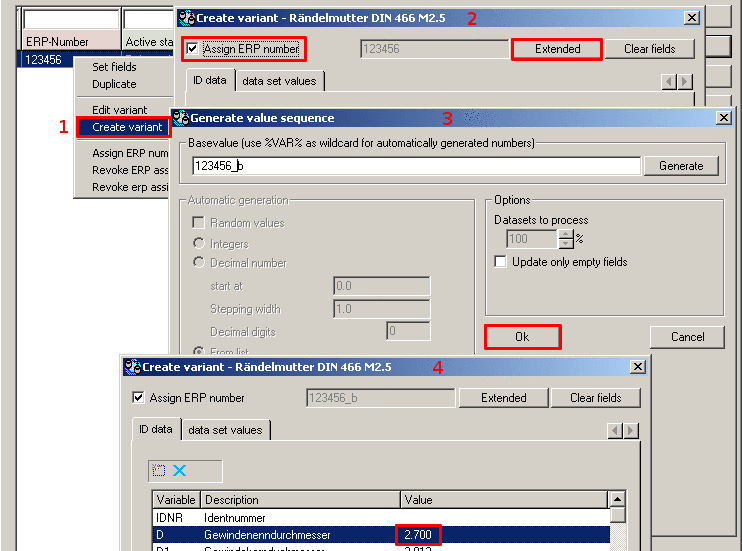

Simple example with only one single condition (see above figure):

In order to import all source files, for example, choose the following setting:

Meaning: "Document name like anything"

Complex example with a combination of queries

When clicking on the respective icon, you can create several queries:

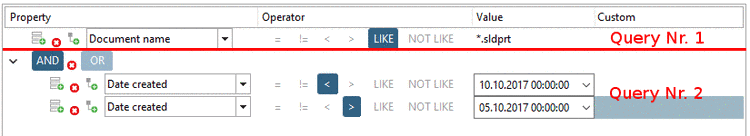

The following figure shows two queries:

Query No. 1: All parts with file extension *.sldprt are imported. Conditions of query 2 are not considered here.

Query No. 2: All parts created between 10/05/2017 and 10/10/2017, are imported. The condition of query 1 is not considered here. Query 2 also imports parts with file extension .sldasm in this example.

In the Property column, in the list field, you can also select the CSV option, for example (regardless of whether the data source is file based or PDM based). Always use this option if no search is performed, but a list of parts to be imported is provided by the customer.

The method how the data should be read, can be determined in the configuration file

pdmproxies.cfg, in the specific PDM block. There, activate the adequate key and set the respective value.

There are the two filter modes Exclude And Include:

The filter can be used both for filtering CAD models And for filtering meta data:

Input: Determine the type of input data:

![[Note]](https://webapi.partcommunity.com/service/help/latest/pages/en/3dfindit/doc/images/note.png)

Note Not only setting within PLM Synchro matter but also settings within Creo. So please also regard the notes under Section 2.3.7.6, “Conversions from Creo to "STEP" format” in PARTsolutions - Administration Manual.

Output: In the list field, select the desired output format

For this option the license PSADDONS*ADVANCEDTOPO is required. If it is available, enhanced features/topology information is read in like Sphere, Torus And Elongated Cylinder. The other features like Hole, Cylinder, Cone, Opposite Planes, Pattern, Fillet, etc. are read in with much better quality.

Via browse button , select the target directory.

![[Note]](https://webapi.partcommunity.com/service/help/latest/pages/en/3dfindit/doc/images/note.png)

Note When using distributed services the path entered under Destination directory has to be reachable from every client.

If locally executed, at the best, leave the entered default path.

Determine catalog name And whether preview images shall be generated.

Generate preview: If preview images shall be automatically created, activate the check box.

In the pipeline you can make specific adaptions. On this see Section 1.2.3, “Distributed services”.

Catalog name: Determine catalog or directory as destination for imported parts.

In the summary, check if all settings have been made correctly.

When clicking on , the wizard is finished And the process view with pipeline is displayed in PARTdataCenter.

Before starting the PLM Synchro process, please make sure that the path of the exe file of the used CAD system is entered under configuration file

pcadmanager.cfg-> blockiface.<cadname>-> keyCommand_0.Now you can click on the start button

in order to execute the PLM Synchro

process.

in order to execute the PLM Synchro

process.The process can be paused

or stopped

or stopped  anytime.

anytime.![[Note]](https://webapi.partcommunity.com/service/help/latest/pages/en/3dfindit/doc/images/note.png)

Note In the Dashboard, you can see detailed information on all processes (finished, cancelled, running or failed). See Section 1.2.3.3, “Dashboard”.

Open PARTdataManager. In the Part view, under Structure -> Catalogs, now your catalog created by PLM Synchro is displayed.

Meta data have been transferred to the characteristic attribute table.

Under Topology information the respective information is displayed.

If problems arise, you will be informed via docking window Messages.

In PARTdataCenter -> Catalog view, via context menu command under Workspace -> Processes -> Add PLM process, you can open the Wizard window anytime.

For an existing process you can call the Wizard with the Edit PLM Synchro process command.

![[Tip]](https://webapi.partcommunity.com/service/help/latest/pages/en/3dfindit/doc/images/tip.png)