Drilling patterns are described using the CNS_CP|4|2 classification. The associated connection point defines the associated coordinate system.

The aim of this classification is to provide information for NC machines or to define the geometry of fastening points in general. In principle, this can be achieved in two ways:

General outline of external data (see Section 5.12.9.8.2, “Definition of outlines / contours”)

We will deal with option 1 here. Option 2 is dealt with in a separate chapter.

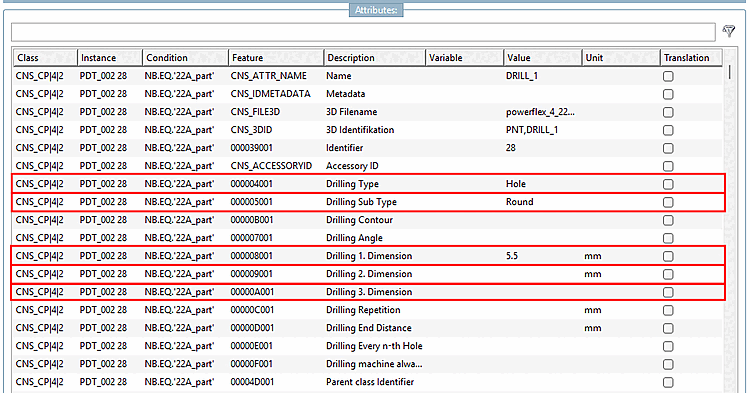

The classification provides the following attributes:

The Drilling Type attribute defines whether the thread is a hole, an inch thread or a metric thread.

The following forms are offered via the Drilling Sub Type attribute:

The three numerical attributes Drilling 1st dimension, Drilling 2nd dimension and Drilling 3rd dimension control the dimensions of these shapes, whereby the zero point is defined by the connection point.

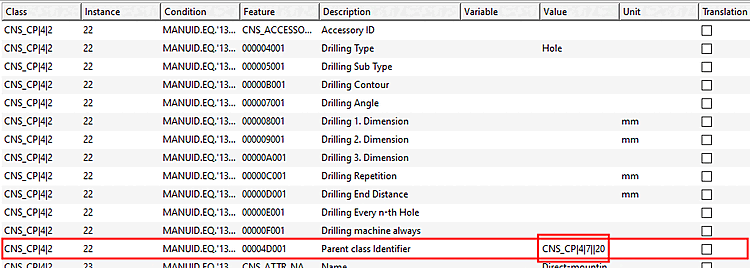

The Parent class identifier attribute describes the internal linking of the given drilling pattern to the associated Mounting Description. In this way, entire sets of CNS_CP|4|2 classifications can be assigned in associated Mounting Descriptions.

The scheme described below is used in the same way in several places and is formulated here for clarification.

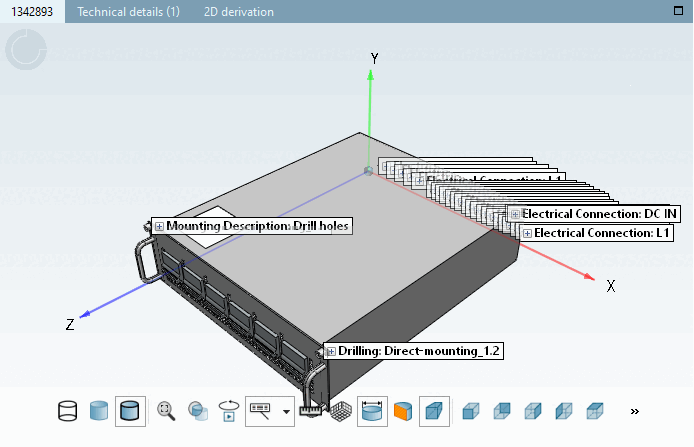

The part shown in the following figure has a Mounting Description (CNS_CP|4|7) and two Drilling Patterns (CNS_CP|4|2).

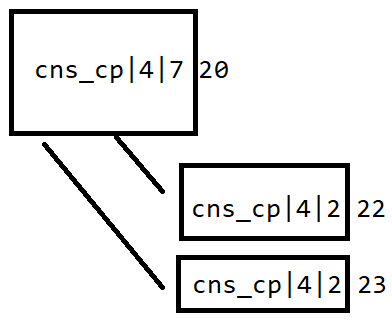

In this part, the two drilling classifications are assigned to the Mounting Description as shown in the following graphic.

In the classification, this is achieved by the attribute Parent class identifier. The subordinate classification elements are assigned to the parent elements in the following form:

Klassen-Identifier || Klassen-Instanz

The drilling pattern with instance 22 results in the string CNS_CP|4|7||20 as shown in the following figure.